No products in the basket.

How to use Shape K and examples

Select tip shape

How to use Shape K and examples

This type has a shape like a knife and is capable of soldering by applying the tip in 3 ways: line, face and point. It is used for soldering at narrow pitches, correction of bridging and drag soldering.

Soldering tiny chip parts such as 0603

| Put the tip to the leads while laying down the entire blade. Some IC is specified by manufacturer not to be touched electrode by tip end. The other tip shapes are recommended. |

Drag soldering

| PTH Put the tip to the leads while laying down the entire blade and drag it slowly. Apply flux to leads and land pads before soldering. It prevents the troubles such as solder bridge. * Lay the blade down to thoroughly transfer sufficient heat to the pattern. |

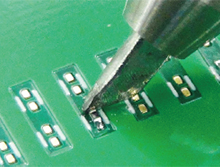

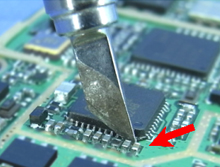

| QFP Put the tip to the leads while laying down the entire blade and drag it slowly. Apply flux to leads and land pads before soldering. It prevents the troubles such as solder bridge. * Lay the blade down to thoroughly transfer sufficient heat to the pattern. |

Correcting Bridging

| If the bridge amount is small Stand the blade on edge and drag the tip slowly. Please operate with clean tip. * Do not stand the blade up at too steep angle. Doing so will damage the P.W.B. |

| If the bridge amount is large Lay the blade down and drag the tip slowly. Please operate with clean tip. |

Soldering at the narrow pitches

| Stand the blade on edge and put the tip end on the leads of the IC chip.

|