No products in the basket.

N2 System – setting temperature

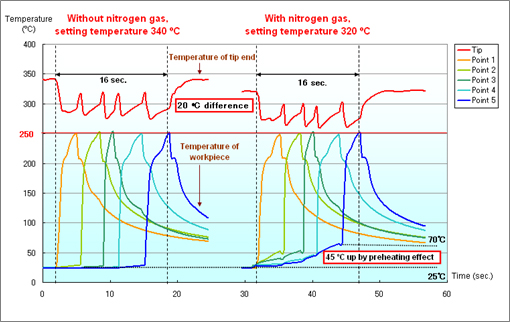

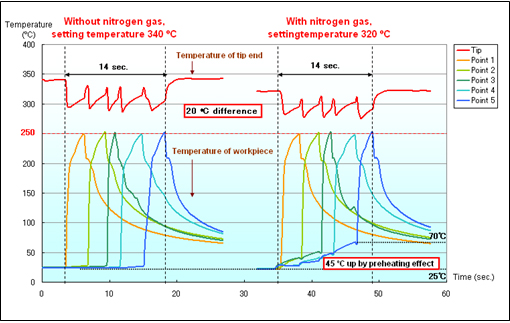

Preheating effect of N2 system allows for setting at low temperature and protecting heat-sensitive components. Look at the following graphs showing the difference of soldering time with / without nitrogen gas in case of HAKKO FX951 Set and HAKKO FX838.

| Thermally-controlled high-power compact type (Digital) as a standard soldering iron for any soldering situation |

| High power 150W soldering station suitable for soldering from large to fine components (Digital)for components requiring a large amount of heat |

HAKKO FX951

| Test method: | Measure the time until the workpiece reached to 250℃ at 5-points; setting temperature is 320℃ with nitrogen gas and 340 ℃ without nitrogen gas.: |

| Board | Paper phenol copper, single-sided |

| Component | Connector |

| Tip shape | T12-D24 without nitrogen gas T13-D24 with nitrogen gas |

| Setting temperature | 340℃ without nitrogen gas 320℃ with nitrogen gas |

| Solder | Lead-free solder (Sn-3Ag-0.5Cu) ø0.5 |

*Please refer to above values, which vary depending on soldering condition.

HAKKO FX-838

| Test method: | Measure the time until the workpiece reached to 250℃ at 5-points; setting temperature is 320℃ with nitrogen gas and 340ºC without nitrogen gas. |

| Board | Paper phenol copper, single-sided |

| Component | Connector |

| Tip shape | T20-D24 with / without nitrogen gas |

| Setting temperature | 340℃ without nitrogen gas 320℃ with nitrogen gas |

| Solder | Lead-free solder (Sn-3Ag-0.5Cu) ø0.5 |

*Please refer to above values, which vary depending on soldering condition.

Comment As the above, when using N2 system, soldering time is the same even at the 20 ℃ lower set temperature by preheating effect. Preheating alleviates a rapid heat and allows a lower temperature setting, resulting in protecting heat-sensitive components.