No products in the basket.

Maintenance inspection for station-type soldering irons

| Top page for Maintenance inspection for station-type soldering irons | |

| Inspection 1 | Checking the leak voltage |

| Inspection 2 | Checking the tip-to-ground resistance |

| Inspection 3 | Checking the tip temperature |

Inspection 2. Checking the tip-to-ground resistance

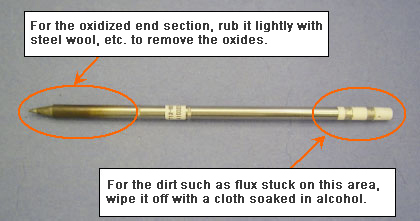

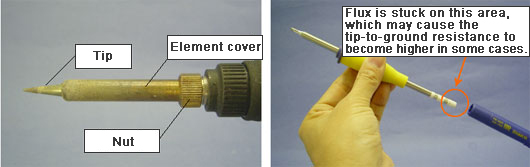

Oxide and flux stuck on the tip, element cover and nut will cause the tip-to-ground resistance to become higher. As a result, the leak voltage will become higher; therefore, periodically check the tip-to-ground resistance. * For the tip-to-ground resistance, let the current temperature increase to the set temperature to make the temperature stable before measurement.

How much tip-to-ground resistance is normal?

As with leak voltage, the lower the tip-to-ground resistance, the better. The MIL standard which has been abolished at present specifies that the resistance is designated to be lower than 5Ω; therefore, all HAKKO station-type soldering irons have been delivered with the resistance set to 2Ω or less which is stricter than that of the MIL standard. * The MIL standard is a US military-based standard and the standard MIL-STD 2000A regarding the soldering irons has been abolished.

If the tip-to-ground resistance is higher, what actions should be taken?

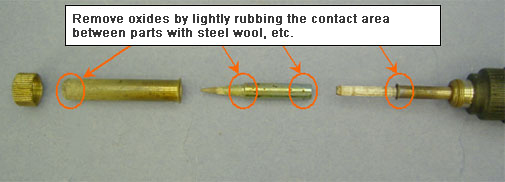

Polish the contact sections such as the tip and element cover with sandpaper, steel wool, etc. to remove any oxide films.

An oxidized tip causes the wetting characteristics to deteriorate. The HAKKO FS-100 is convenient to use for recovering the tip wetting characteristics.