No products in the basket.

Maintenance inspection for station-type soldering irons

| Top page for Maintenance inspection for station-type soldering irons | |

| Inspection 1 | Checking the leak voltage |

| Inspection 2 | Checking the tip-to-ground resistance |

| Inspection 3 | Checking the tip temperature |

Inspection 1. Checking the leak voltage

The following factors cause electric current to be leaked from the tip to the P.W.B. and the device, resulting in adverse effects on objects being soldered. For this reason, check the leak voltage periodically.

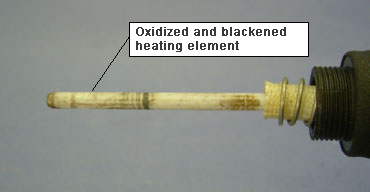

Even though an insulative ceramic material is used, long-term use has caused the heating element to deteriorate and the leak voltage to increase.

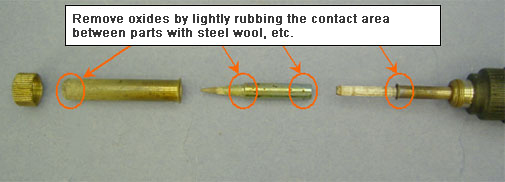

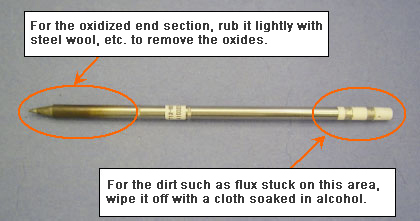

Accumulation of oxides on the parts such as tip/element cover caused contact failure to be generated and leak voltage to increase.

How much leak voltage is normal?

The lower the leak voltage, the better. The MIL standard which has been abolished at present specifies that the leak voltage is designated to be lower than 2mV; therefore, all HAKKO station-type soldering irons have been delivered with the leak voltage set to 2mV or less in conformance to the MIL standard. * The MIL standard is a US military-based standard and the standard MIL-STD 2000A regarding soldering irons has been abolished.

<

Measure leak voltage after adjusting the temperature setting to the maximum.

When the leak voltage is measured at the highest temperature, the highest leak voltage will be recorded. If normal results are obtained even in unfavorable conditions such as at the highest temperature, it is judged that normal results will be obtained at other temperature settings. (This method is based on the MIL standard.)

If the leak voltage is higher, what actions should be taken?

1. If the heating element has deteriorated Replace the heating element with a new one. The heating element will be oxidized and blackened in this case.

2. If oxides have accumulated on other parts Remove oxides with steel wool or fine-grade sandpaper.

An oxidized tip causes the wetting characteristics to deteriorate. The HAKKO FS-100 is convenient to use for recovering the tip wetting characteristics.