No products in the basket.

Why doesn’t solder flow evenly onto a tip though it is brand-new?

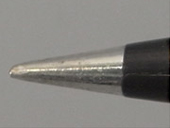

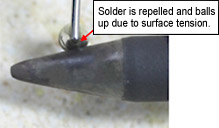

Even a new tip will start to oxidize and solder will stop wetting if the iron is left on for 30mins or more

| After iron has been left on for 30 min Tip temperature is 470°C (Measured with HAKKO FG-100) |  |

| New tip | Tip turns black due to oxidation Solder will not wet to the tip in this state even if the tip is new. |

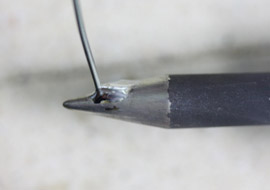

Turn the power on, wait until the solder starts to melt, and then feed a generous amount of solder to coat tip. If you then leave the iron as it is, you should be able to maintain wetting performance like that shown in the photo.